If you’re a consumer of plastic products, you’ve probably heard of Polyvinyl chloride (PVC), a synthetic polymer made of vinyl chloride. If you’re not familiar with the material, you’ve probably heard that it’s non-biodegradable, contains a number of toxic additives, and emits toxic fumes. But what exactly is PVC, and why is it dangerous? Let’s take a look.

Polyvinyl chloride (PVC) is a synthetic polymer of vinyl chloride

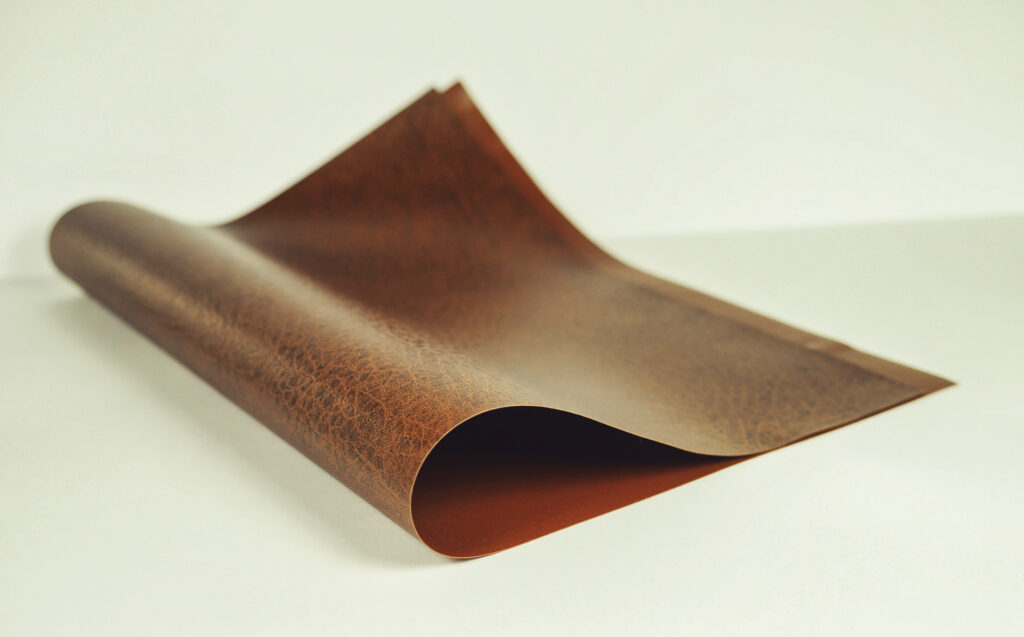

Vinyl is a versatile synthetic polymer that can range from rigid industrial pipes to thin and flexible wallcovering. The material can be made of any color that is both durable and cost-effective. In addition, more than three-quarters of all vinyl is used in building applications, making it an environmentally-friendly material. Unlike other plastics, vinyl requires no painting and can be cleaned with mild chemicals.

The production process for PVC floors begins by polymerizing the monomer vinyl chloride. Vinyl is a carbon-based compound containing a functional group -CH and the chloride molecule consists of a chlorine-containing ring. The resulting compound is a white solid, with a chemical formula of -CH=CH2.

PVC has a high level of resistance to sunlight, chemicals, and oxidation in water. Many vinyl products use plasticizers as they are inexpensive and compatible with the polymer. This means that most vinyl products contain these additives. However, there are other synthetic polymers available. For example, the phthalate plasticiser is used in electrical cables, toys, and lifesaving medical devices.

PVC is a synthetic polymer of vinyl chlorides. It is the second most abundant synthetic polymer after PE in terms of production and consumption. It is produced by combining the monomer with other chemical compounds to form a polymer. This process involves adding stabilizers, plasticizers, and modifiers to the vinyl chloride. The polymer is mixed with other substances, like ethylene, to create the final product.

PVC was accidentally discovered twice in history. First by a French chemist, Henri Victor Regnault, and then by a German named Eugene Baumann in 1872. He had the material patented in Germany, but didn’t know where to use it. He failed to find a commercial use for it until 1925. The invention of PVC made it more widely available, gaining widespread use.

It is a relatively inexpensive plastic that is highly resistant to water and fire. This property makes it a good choice for use in water pipes, raincoats, and shower curtains. PVC is also fire retardant and contains chlorine atoms, which inhibit combustion when burned. Because of this, PVC is often preferred over other materials when it comes to electrical wire insulation in high-fire risk applications.

It is non-biodegradable

There are several ways to tell if a product is made of PVC. You can look for the stamping. However, not all PVC products have this stamping. If you’re unsure, you can always try contacting the manufacturer and voicing your concerns. There are also new materials that mimic the properties of PVC but are engineered to break down in landfills without emitting toxic gases. But these new materials are not available widely yet, and they’re quite expensive.

Plastic is a very common material, but PVC is not biodegradable. When it burns, it releases a number of harmful chemicals. Phthalates are heavier than air and can cause damage to the reproductive system and kidneys. Furthermore, the chemicals in PVC leach out into the soil. PVC isn’t biodegradable, so its recycling is imperative for the environment. This makes it vital to recycle old PVC banners and posters.

Recycling is another important step in making PVC more eco-friendly. The process of dechlorination, or ‘de-chlorination’, allows valuable chemicals and energy to be recovered. Once dechlorinated, PVC can be buried or used as a hydrocarbon feedstock. But these processes produce a high amount of chlorine and HCl, which can be dangerous to humans and the environment.

The process of biodegradation is different for different plastics. Non-biodegradable waste consists of plastics that do not break down. Many plastics are manufactured to withstand high temperatures and withstand the harsh environment. This makes them difficult to break down after use. But there is hope for those that don’t want to give up plastics completely. Most plastics are biodegradable and there are many alternatives.

Non-biodegradable materials can cause a lot of problems. When exposed to the environment for a long time, they can cause pollution. Plastics oxidize to emit toxic salts, which can be carcinogenic and deadly for humans, animals, and plants. Non-biodegradable waste can also disturb aquatic life and propel eutrophication. The environmental effects of non-biodegradable waste are enormous.

It emits toxic fumes

The production of PVC uses chlorine, one of the most toxic substances on earth. Not only does it pollute the air, but it also contaminates the environment and humans during production and disposal. While all plastics are a major concern, PVC is perhaps the most toxic. Fortunately, there are safe alternatives to virtually all PVC uses, and its use can be phased out over time. Read on to learn more about the health risks associated with PVC.

The toxic fumes produced during the process of cutting and milling PVC are particularly toxic, causing headaches and a clammy feeling. The good news is that PVC is relatively inexpensive and readily available. The bad news is that you can’t avoid breathing these fumes, but you can limit their effects by using protective gear, exhaust fans, and the proper speed when cutting and milling PVC.

The main ingredient in PVC is vinyl chloride, a suspected carcinogen and reproductive toxin. It is commonly used in many PVC products, and children are at risk of exposure from chewing on vinyl toys. Because of the harmful effects of PVC fumes, some of its compounds were banned from children’s products in the U.S. in February 2009. In addition, this chemical was found in a variety of other consumer goods.

Although PVC has excellent tensile strength, it is not stable under higher temperatures and can release noxious fumes when melted or burned. It is therefore recommended to use PVC-free electrical wire insulation for such applications. In addition to this, PVC is widely used in the construction industry. Aside from being cheap, it is also widely available, relatively inexpensive, and has high tensile strength, making it the ideal material for many different applications.

The best way to check for PVC-containing products in your home is by consulting a plumber, building contractor, or remodeling contractor. However, this task may be difficult if you are not remodeling your home any time soon. A professional can do the job for you, although you may have to spend $400. The test results can help you determine what products are causing the bad air quality in your home. However, it is important to note that some PVC products are easier to detect than others, so you will want to take precautions to avoid them.

It contains toxic additives

To make PVC into toys and other products, it must be mixed with a series of additives. These additives can include toxic plasticizers, stabilizers with heavy metals, and fungicides. Some of these substances are lost in the air during manufacturing. Consequently, if your child plays with a new toy made of PVC, the smell could be toxic. These additives may also leach into food.

Dioxin and chlorinated chemicals are highly toxic and can migrate to other parts of the world, but some communities are hit harder than others. PVC is manufactured in 14 U.S. plants that discharge huge amounts of toxic chemicals. The discharged pollutants affect nearby drinking water supplies, and the on-site incinerators spread dioxin into the air. Environmentalists are warning that the use of PVC could be a serious health hazard.

Best Buy, the largest consumer electronics retailer in the United States, is facing challenges with its use of PVC. Many consumers are concerned about the environmental impact of the company’s toxic waste. To combat this, As You Sow engaged the company’s senior managers and withdrew the shareholder resolution. Best Buy’s practices have since changed. But the debate over PVC and toxic additives in electronics continues. So, it’s time to stop using PVC-containing plastic products.

These plastics emit dioxins, a group of semi-volatile organic compounds, into the air. This substance can lead to respiratory problems, and is highly toxic when burned. It also leaches dioxins, which are among the most potent carcinogens known. In addition to being highly toxic, PVC is also difficult to recycle. It is a contaminant in other plastic recycling.

The chemical additives that PVC releases into the environment have a broad spectrum of effects. Most of these additives are leachable into aqueous solutions, and so may increase the exposure of aquatic animals. For example, an early-life zebrafish exposed to PVC had a higher expression of metallothionein 2, a metal-binding protein. Other biomarkers, such as p-adrenol, showed no association with PVC exposure.